- Overview

- Inquiry

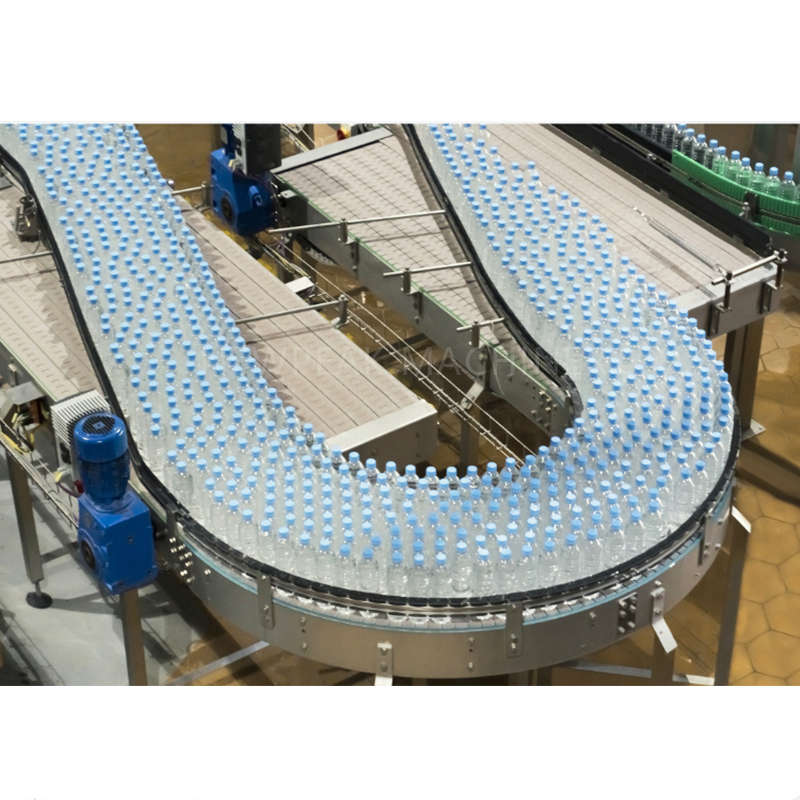

- Related Products

Newpeak Machinery

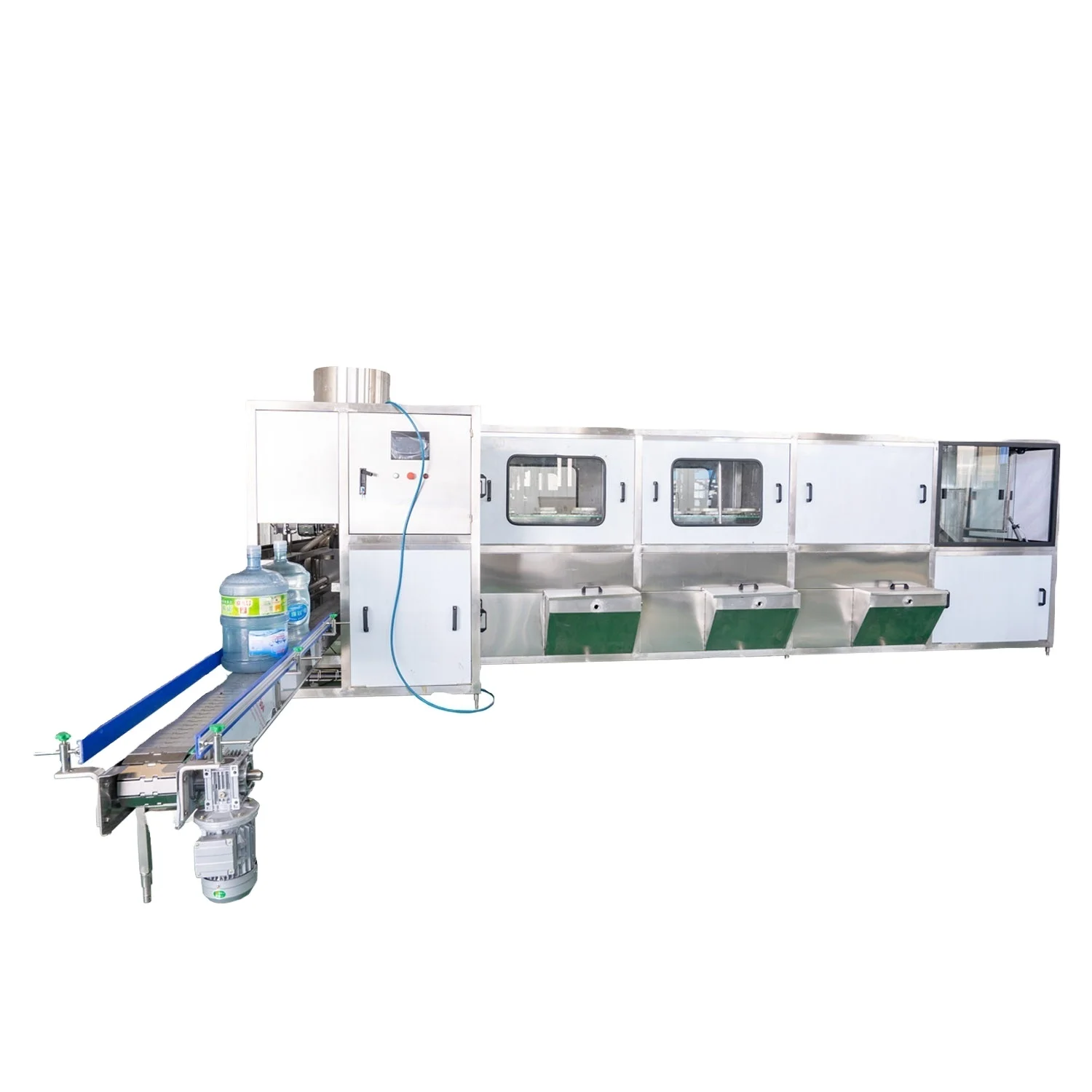

Introduced their item is latest, the Mineral Pure Water Filling Machine, which will be perfect for filling mineral water or purified water into containers or jars. This machine is created specifically for tiny to medium-sized businesses that want a dependable and water is efficient that filling.

The Mineral Pure Water Filling Machine has an advanced PLC control system, enabling effortless operation and precise control of the method is filling. The system is very automatic, meaning that the stuffing process is quick, accurate, and consistent. The device normally built with a touch screen user interface, which makes it easy to put up and adjust the process is filling various kinds of containers or jars.

Perhaps one of the most notable features of the Mineral Pure Water Filling Machine is its level is a complete lot of. The device is manufactured out of top-notch metal is stainless designed to be simple to clean and maintain. This helps to ensure that there was contamination is minimal with the water during the filling process, which really is a key requirement of creating safe and mineral water is high-quality.

The machine is also highly versatile, as they can be used to fill containers or jars of different shapes and sizes. The filling procedure is adjustable, permitting accurate filling of various volumes of water. This will make it an answer is ideal companies that want to fill water containers or jars of different sizes and volumes.

The Mineral Pure Water Filling Machine can be made for simplicity of upkeep and make use of. A fault is had by the device detection system that identifies any nagging dilemmas or malfunctions within the filling procedure. This enables for quick and troubleshooting is effective downtime that minimizing reducing the possibility of damaged or wasted product.

Capacity (500ml bottles):2000-20000BPH

Suitable bottle shapes:PET circular or square

Bottle diameter (mm):φ50-115mm

Bottle height (mm):160-320mm

This pet bottle drinking water pulp filling machinery has washer, filler, and capper three functions in one body, total process is automatic.

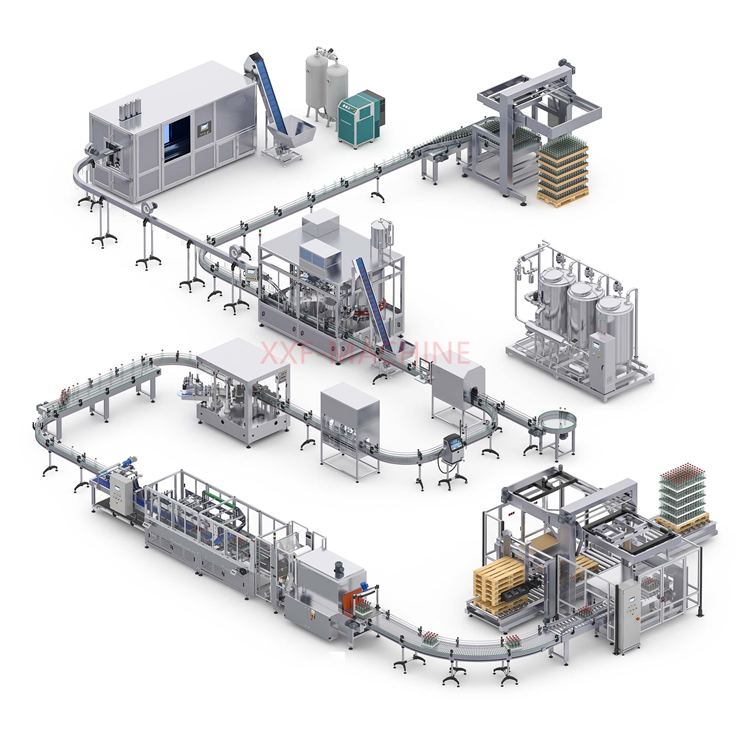

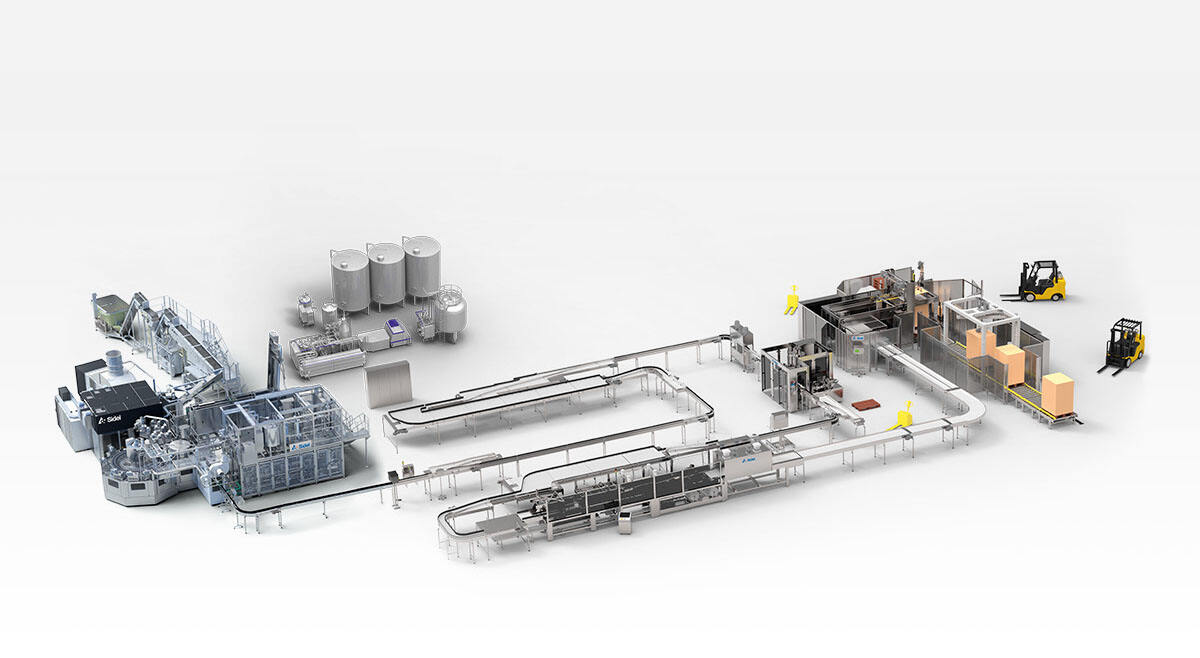

Automatic 500ml Bottle Bottled Water packing and Filling Machine

It is suitable for high temperature resistant PET/Glass/Aluminum bottled drinking water filling. It applies advanced micro-pressure gravity type filling principle, with perfect recirculation system, also can reach separately gas return, without contacting with material, and avoid secondary pollution and oxygen. It is made of high quality SUS304 stainless steel.

Special design for washing part

Special design for capping part

Main Features.

Model |

CGF8-8-4 |

CGF14-12-5 |

CGF18-18-6 |

CGF24-24-8 |

Production Capacity

|

2500BPH~3000BPH |

3500BPH~4000BPH |

6500BPH~8000BPH |

10000BPH~12000BPH |

Bottle height |

330mm |

|||

Bottle diameter |

50~100mm |

|||

Bottle volume |

0.2~2L |

|||

Rinsing pressure |

0.2~0.3Mpa

|

|||

Rinsing water consumption

|

0.5T/H |

|||

Filling precision |

±2~3% |

|||

Power |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,1.5Kw |

3ph,380V/50Hz,2Kw |

3ph,380V/50Hz,3Kw |

Q: Are you a manufacturer or a trading company?

A: We are the source factory with 25 years of manufacturing experience in beverage machinery. Located in Jinfeng Town, Zhangjiagang City, Jiangsu Province, and China. The transportation is convenient, very close to Pudong Airport and Sunan Shuofang Airport. If your itinerary includes a factory visit, we will pick you up.

Q: How long is your delivery cycle after you order the machinery?

A: Generally it is 40 working days.

Q: Do you have a relevant after-sales system?

A: We have a Perfect after-sales system.

1: 12 months warranty.

2: Many-to-one service, we will solve basic problems through phone, email, WhatsApp, WeChat and video calls. The operation manual will be sent with the machine or via e-mail.

3: If conditions permit, the engineer will go to the buyer's factory to install and test the machine, and train the buyer's staff on how to operate and maintain the machine.

Q: If I want to buy a machine, what information do I need to tell you?

1: What liquid do you want to fill?

2: What is the capacity and height of the bottle?

3: What is the output in one hour?

4: Related water quality analysis reports, etc.

5: Required mechanical voltage

Q: How to ensure that you deliver goods on time and ensure the safety of my funds?

1: We guarantee the on-time delivery and quality of the equipment you purchase through the credit insurance service of the Alibaba platform.

2: With the letter of credit, you can easily lock in the delivery time.

3: After visiting the factory/video watching the factory, you can ensure the authenticity of our bank account.

Q:How do you ensure the quality of the machine?

1: To ensure the accuracy of parts. We are equipped with a variety of professional processing equipment, plus professional processing methods accumulated over the years.

2: Before the machine is assembled, each part is inspected by the inspector.

3: Assemble machines, all with masters with more than 5 years of work experience to operate.

4: After all the equipment is completed, we will connect all the machines and allow at least 12 hours for a complete production line. To test its stability

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ