Comme nous l'avons dit, les machines de remplissage de boissons sont des appareils incroyables qui peuvent également être utiles pour d'autres choses. Elles vous fournissent ces sodas et jus de fruits dans des bouteilles et des canettes. C'est ce que beaucoup d'entreprises utilisent pour mettre en canette leurs délicieuses boissons, et elles assurent un fonctionnement fluide. Vous vous êtes peut-être déjà demandé comment ces merveilleuses machines effectuent l'inspection. Si vous souhaitez en savoir plus sur leur fonctionnement, continuez à lire.

Comment fonctionnent les machines de remplissage de boissons

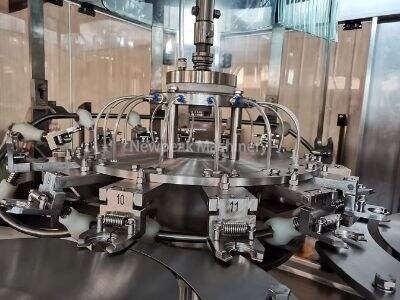

Tout d'abord, lors du remplissage des bouteilles/canettes, les ouvriers placent des bouteilles/canettes vides sur une bande transporteuse qui se déplace avec précaution. Cette bande joue un rôle important pour acheminer toutes les bouteilles et canettes vers l'appareil. Les pinceurs maintiennent les bouteilles ou canettes en place lorsqu'elles sont reçues par le système de remplissage. Les pinceurs sont montés sur un bras sur l'axe Z. Ce mouvement est nécessaire pour stabiliser les bouteilles et canettes afin qu'elles ne basculent pas pendant le remplissage.

Puis, les machines fabriquées par Zhangjiagang Newpeak Machinery insèrent la quantité parfaite de liquide dans les bouteilles et canettes. Les réservoirs de boissons sont connectés à la Machine de remplissage d'eau par des tuyaux, afin que le liquide puisse s'écouler vers la buse de remplissage. La buse est positionnée directement au-dessus, un petit trou permettant au liquide de s'écouler parfaitement. Une fois le conteneur rempli, la buse se rétracte et s'éloigne. Les vigiles costauds relâchent leur emprise pour qu'il puisse continuer sur ce tapis roulant vers l'étape suivante.

L'Anatomie Des Machines De Remplissage

La machine de remplissage elle-même comporte plusieurs composants vitaux qui travaillent en harmonie pour remplir correctement chaque bouteille ou canette. Le système SSMD41 inclut des capteurs pour mesurer le poids du liquide dans chaque contenant, ainsi que des vannes qui régulent l'écoulement dans ces contenants. De plus, il y a des contrôles limites qui ajustent le niveau de remplissage de chaque contenant et activent également des capteurs qui mesurent le nombre de bouteilles/canettes qui ont été remplies. De cette manière, la machine connaît toujours tout.

En plus de simplement remplir les conteneurs, divers autres aspects du machine de remplissage processus peuvent être mis en œuvre, tels que l'étiquetage, le bouchage et le scellage des bouteilles ou des canettes. Ces pièces supplémentaires garantissent que chaque bouteille ou canette est correctement étiquetée et bien scellée pour la livraison au public. Cette partie est essentielle car personne ne veut boire dans un conteneur qui n'a pas été correctement fermé.

Comment les machines de remplissage de conteneurs remplissent-elles correctement les conteneurs ?

Capacités de remplissage précis du liquide - Le aspect le plus important de la boisson Machine de remplissage de boîtes en aluminium est qu'ils peuvent remplir les liquides de manière exceptionnellement précise. Ainsi, chaque conteneur reçoit ce qu'il devrait avoir en volume. Cela est très important car si un conteneur contient une quantité incorrecte de liquide, cela peut modifier l'arôme ou, pire encore, endommager votre produit. Par exemple, s'il n'y avait pas assez de soda dans la canette, elle aurait un goût plus fade.

La machine dispose même de capteurs et de contrôles qui mesurent le liquide versé dans chaque contenant pour atteindre ce niveau de précision de remplissage. Toutes ces parties interagissent pour s'assurer que le liquide est dispensé en une quantité prédéterminée à chaque utilisation. Ils peuvent ajuster encore plus finement tous les changements d'entrée/sortie pour garantir que chaque emballage est rempli exactement selon les spécifications. Ainsi, vous savez à quoi vous attendre avec votre boisson.

Aperçu sur les machines de remplissage de boissons

Donc, les piles derrière les machines de remplissage de boissons fonctionnent. Les machines sont multidimensionnelles, il y a de nombreux composants mobiles qui travaillent en tandem pour produire un haut niveau d'efficacité. Chaque partie, des grippers qui tiennent les contenants aux pompes qui les remplissent de liquide, a un travail spécifique à accomplir correctement pour que chaque contenant soit bien rempli. Ce sont certaines des machines les plus importantes grâce auxquelles vos boissons préférées sont préparées rapidement, vous pouvez en avoir quand vous le souhaitez. Les boissons emballées sont transportées et conservées fraîches à l'aide de ces machines ; sans elles, il serait difficile de conditionner ensemble les boissons pour nous.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ