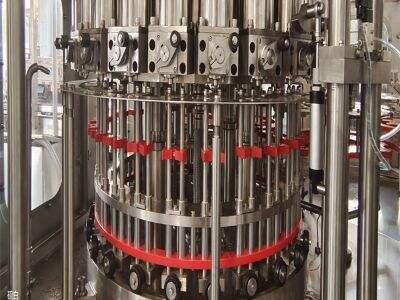

Zhangjiagang Newpeak Machinery focuses on innovative features for automatic juice filling machines. These machines are important for filling bottles with the product efficiently. This article explains where to purchase the latest automatic juice filling machine and issues with automatic juice filling.

Buy the Latest Automatic Juice Filling Machines

Purchasing the latest automatic juice filling machines from Zhangjiagang Newpeak Machinery is a suitable and feasible option. The machines are designed with innovative products that facilitate fast operations of the filling machines while ensuring the bottles are perfectly filled. The juice production line can be purchased directly from the company’s official website or its licensed distributors. The suppliers undertake land training to equip with the required skills and knowledge about the machines, providing expert guidance and consultation services. It is important to consider acquiring the filling machines from a reputable and registered supplier that guarantees the products are of high quality and provide free after-sales service, among others.

Common Issues with Automatic Juice Filling

The automatic juice filling machines encounter some common issues. The first and common issue is calibrations of the machines, which malfunctions to stop the filling machines after realizing a given value for the filling level. Regular calibration ensures that the machines continue to operate without errors. Another common problem is clogging of the filling nozzles, preventing the filling projects and may take downtime. Cleaning is the friend of the machine to avoid clogging issues. Electrical issues and malfunction sensor can also transpire when the automatic juice filling line is not inspected regularly. Proper repairs and inspections help to identify the issue hence running the automatic juice filling smoothly.

To purchase the latest automatic juice filling machines, it is imperative to look for a well-established supplier such as Zhangjiagang Newpeak Machinery. Although these machines can ease juice production, they are prone to some common problems, including calibration issues, clogging, and electrical faults. These issues should be addressed shortly and ensure maintenance is done on time. Proper maintenance of automatic juice filling machines will help enhance efficiency and achieve the production goals more readily.

Market trends for an Automatic Juice Filling Machine

Several trends have been witnessed in the automatic juice filling machine market. The key trend is the manufacture of efficient and eco-friendly machines. Manufacturers such as Jiangsu New Peak Machinery are developing machines that can fill juice bottles faster and accurately and minimize energy use and wastage. Advanced technology has also been integrated into the automatic juice filling machines. This includes touch screen, automatic cleaning devices, and machine monitoring systems. The technological development has facilitated the safe attachment and maintenance of the machines, thus boosting production. Such machines also have high uptime during production. Additionally, there is severe competition for machines that can be used on different bottles. The company designs machines tailored according to the owner’s bottling needs. The adjustments on the bottle do not require the shutdown of the machine. The automatic juice filling machine market is tailored to the needs of the industry. The manufacturer offers optimum production, supporting the smoothness of the production of juice.

Finally, proper maintenance remains key to the normal and efficient functioning of the automatic juice filling machine. For the effective functioning of the machine, here are some maintenance tips for the juice maker:

-Regularly clean and sanitize the machine to prevent contamination and preserve product quality.

-Permit to check the defective part or the wearing part, including seals and gaskets.

-Proper lubrication of the machine to reduce friction and thus elongate the shelf life of the machine.

-Consistent and regular monitoring of the machine for any breakdown and quick fix of the defects to prevent spiral breakdown. Proper training of the operators on the usage and maintenance procedures of the public until it is clean and in good form.

By following all the above maintenance tips, the user is assured of the existence of the automatic juice filling machine in good condition and, hence reduced downtime. Reduced downtime means an increased level of production to the juice maker, thereby increasing the profit of the owner.

What Do You Need to Know About the Newest Automatic Juice Filling Machine Designs?

The most recent innovation in the machine industry incorporates the most advanced automatically filling juice machine technique to foster efficiency and productivity in its process. These technics include high-speed products which: SKU fill more affordable in an hour through increasing the number of fittings, ensuring levels by the utilization of precision, user- SKU simplifying buttons. Stay clean by the running machine sanitation method and allowing different shaped SKU bottles.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ