Boosting Production with Automated Bottle Filling Systems

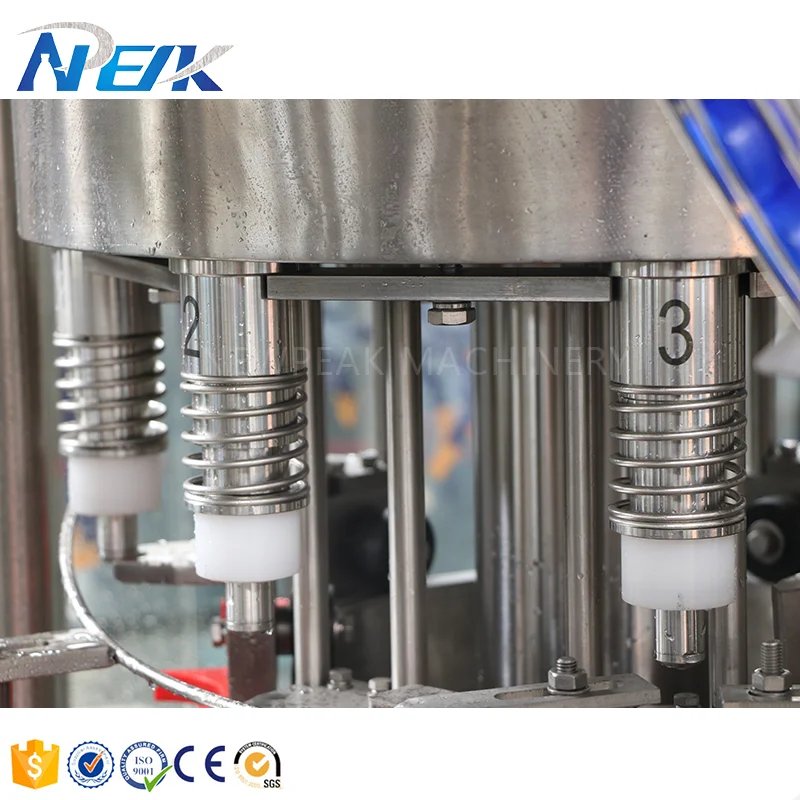

Enhanced filling production is the first and the most effective way of increasing the productivity of a plant. A bottle manufacturing plant can produce more bottles when the rate of production for bottle filling machine dramatically increases. Installing automation technology can help immensely. Automation technology enables the use of machines to perform some tasks in the plant. When machines fill, cap, and label bottles, workers in the plant will be free to work on other important things around the plant. Additionally, errors will be minimal, and the rate of production will be faster than when humans perform these activities. For example, the Zhangjiagang Newpeak Machinery recently installed a new automated filling system in their plant. The system is filling baskets 30% faster than any other filler. The implication is that every load, or basket, can be filled faster, enabling more bottles to be filled in a limited period and, finally, improving the overall production. Second, proper scheduling will help increase a plant’s productivity, primarily when the production process is running throughout the week.

Maximizing Output Through Proper Scheduling and Efficient Layout Design

Proper scheduling means that there are times when production runs can be allocated multiple resources are work harmoniously. The managers will create proper timelines and schedules that will improve the productivity of the plant. For instance, the Zhangjiagang Newpeak Machinery Manufacturer has planning software enabling them to prepare the production run efficiently for a 20% output increase and no increase in operational costs. Layout and workflow design layout design refer to the initial design practice that guides both physical arrangement and adjustment of the facility layout of the plant equipment and machinery. Setting a plant’;s layout in an orderly manner will be easy for workers in specific sections to move in between the many processes in the plant with less or no delay.

Increasing Productivity with Regular Maintenance and Equipment Management

Conducting Regular maintenance checks are the other ways of increasing Plastic item production. Regular maintenance entails details check on how the equipment pieces are in good shape and following the recommended functionality. Always ensure that all tasks are carried out according to the realization of a limited number of downtimes assumed. Plant technicians should quickly respond to equipment malfunctions to replace damaged or broken equipment and parts of the plant. It is also wise to purchase extra parts that are bound to be used once these are damaged or not operating during the replacement. The regular reorganization will have re-structuring every worker in different categories in the plant. To increase the productivity of a plant in manufacturing.

Using Data Analysis to Identify Bottlenecks and Improve Efficiency

A plant will make more bottles if information collected during production is fed backed and analyzed to deduce the real reasons in bottlenecks in the plant, for instance, collecting data useful for monitoring and analyzing to be able to create smart solutions defined in the life cycle process. This means that the quality productivity maximum is finally exercised to increase the output in bottle production line.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

IW

IW

ID

ID

SR

SR

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

AZ

AZ

KA

KA

UR

UR

BN

BN

BS

BS

JW

JW

LA

LA

PA

PA

TE

TE

KK

KK

TG

TG

UZ

UZ